Customs modernisation is no longer optional. EU and UK customs teams face a shift toward data-driven compliance. Authorities use data to spot patterns across traders and flows, not only to review single entries.

EU Customs Reform pushes more checks into central systems. This increases scrutiny on data quality and on how your processes really work. You also face new regulations such as the Corporate Sustainability Reporting (ESG). The Carbon Border Adjustment Mechanism (CBAM) and the Regulation on Deforestation-free Products (EUDR) increase traceability pressure. One declaration now feeds tax, sustainability, and supply chain decisions. You also see more real-time data and integration demands.

All of this lands in teams that already feel stretched. Most teams are not getting extra headcount. More manual work is not an option.

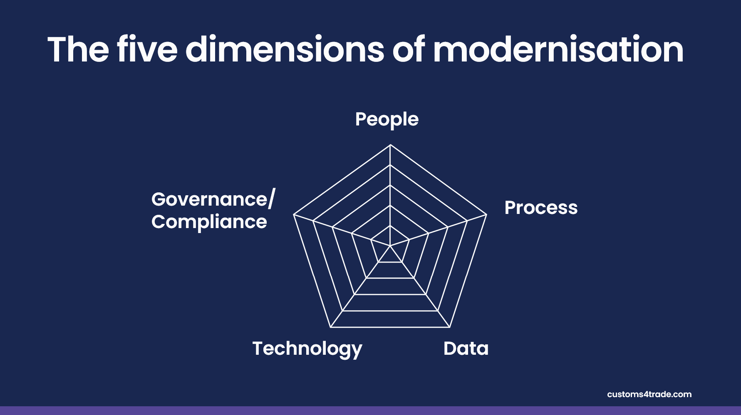

The only realistic way forward is to change how customs work is organised across people, process, data, technology, and governance and compliance. That is what modernising customs operations means.

TL;DR: what you will get from this article

You will learn how to describe your customs setup across five dimensions: people, process, data, technology, and governance and compliance.

You will see where customs teams say they get stuck, using the live poll results from the webinar.

You will learn what automation changes in practice: fewer preventable errors, less retyping, clearer status visibility without chasing updates, stronger control through built-in checks and audit trails, and more time freed up for value-added work instead of fixing mistakes.

Why modernising customs operations matters now

Before the webinar, when people were registering, we asked what the biggest challenge(s) their customs teams face when trying to modernise operations. The top three challenges were clear.

- 43% selected legacy systems and limited integration.

- 39% selected poor or inconsistent data.

- 38% selected dependence on brokers and external partners.

Other pressures showed up, too.

- 30% picked lack of resources or time.

- 26% picked limited visibility and reporting.

- 16% picked difficulty building a business case.

*Note: registrants could select more than one option.

This mix matters. It showed that you are not blocked by one issue alone. You are stuck in a loop of old systems, data gaps, and external dependency. That loop creates manual work. It also hides risk because evidence and status sit across inboxes, files, and broker updates.

Automation matters because it breaks that loop. It reduces retyping, applies checks before submission, and gives you one view of what is happening so you can manage exceptions instead of chasing updates.

What does “modernising customs operations” mean in practice

Modernising customs operations means you move from manual, reactive work to connected workflows where systems handle routine steps and people focus on exceptions.

In the webinar, we used five linked dimensions.

- People: How the role is evolving.

- Process: How consistent execution is across sites, countries, and brokers.

- Data: How you control key fields and changes, and where your “truth” lives.

- Technology: How connected your systems are, and how much re-entry exists.

- Governance and compliance: How you track performance, evidence control, and prevent repeat issues.

If one dimension lags, it pulls the others down. Strong people with weak data still struggle. Tools without clear processes become expensive. Governance without visibility turns into periodic box checks.

What EU Customs Reform changes for EU and UK customs teams

The direction is simple. Customs moves toward central checks and greater data scrutiny. The webinar framed this as a shift toward data-driven compliance, with authorities spotting patterns, not only validating single entries.

For EU and UK teams, this lands as a practical operating requirement. You need consistent data. You need traceable decisions. You need visibility across sites and brokers. You need controls that run as part of daily work, not only during audits.

This is also where CBAM and EUDR raise the bar. Traceability depends on reliable data and on how you manage changes across systems and partners.

The customs modernisation matrix: from manual work to predictive control

We introduced a simple matrix that describes how customs operations tend to evolve.

- At level one, you are manual and fragmented, and manage through effort.

- At level three, you are connected and data-driven, and have structure and some integration.

- At level five, you are predictive and strategic, and use data and automation to anticipate issues instead of reacting.

Most organisations sit in different places across the five dimensions. That is normal. The point is to identify where manual work concentrates and what pulls you back into firefighting.

The Customs Modernisation Matrix

|

Dimension |

Manual |

Standardised |

Connected |

Automated |

Predictive |

|

People |

Reactive admin roles | Defined responsibilities | Skilled analysts | Process owners | Strategic advisors |

|

Process |

Ad hoc | Documented | Harmonised | Workflow-based | Optimised |

|

Data |

Fragmented | Partially structured | Centralised | Clean and validated | Predictive & shared |

|

Technology |

Spreadsheets | Basic tools | Integrated ERP-broker links | Automation platform | AI/analytics layer |

|

Governance/ Compliance |

Reactive audits | Standard Operating Procedures & controls | Key Performance Indicators & dashboards | Real-time monitoring | Continuous improvement |

Note that this matrix is our interpretation of how customs operations typically evolve, based on what we observe. It is not a formal standard.

People: why customs teams need to shift from retyping to steering

The webinar described two worlds.

In the old world, customs is manual and reactive, retyping data, chasing documents, and fixing issues at the end. Information is scattered across inboxes, and most effort goes into coordinating parties, exchanging data, and answering questions.

In the modern world, systems handle routine flows and checks. People work from dashboards and focus on exceptions. Customs keeps strong technical knowledge, and adds skills in tools, analytics, and challenging system outputs. Time shifts from doing to reviewing and steering. Customs sits earlier with supply chain, tax, and finance when decisions get made.

The poll results showed where attendees are today. When asked how they would describe their customs team’s current way of working:

- 26% said they are mostly reactive with manual admin and firefighting.

- 29% said roles and responsibilities are defined, but most work is still manual.

- 29% said repeatable tasks are starting to be automated, but people still drive most activities manually.

- 17% said the team operates system-driven workflows with automation support.

- 0% said customs staff act as strategic advisors using real-time data insights.

Poll Question One: People

How would you describe your customs team's current way of working?

- 26% said they are mostly reactive with manual admin and firefighting.

- 29% said roles and responsibilities are defined, but most work is still manual.

- 29% said repeatable tasks are starting to be automated, but people still drive most activities manually.

- 17% said the team operates system-driven workflows with automation support.

- 0% said customs staff act as strategic advisors using real-time data insights.

One example brought this to life. A food company operated in five countries with many brokers. The customs team spent its time creating broker instructions, doing spot checks, and chasing documents. They automated four of the five countries and re-shaped roles. Two people took additional training and shifted to strategic topics, including preference opportunities and advising procurement on supply chain moves and anti-dumping impacts. They kept a broker for the complex processes they could not automate. They moved the rest of the work into a more centralised setup. Automation helped enable this shift because it removes repetitive admin and frees people to focus on exceptions, control, and decisions.

Process: how to standardise customs workflows without slowing the business

Process can sound boring, but the webinar made a blunt point. In customs, process is where money and risk sit. If workflows and responsibilities are unclear, no system fixes it.

In the old world, the same shipment gets handled differently depending on who touches it. Responsibilities feel fuzzy. Work bounces between people. Key steps live in inboxes. New joiners learn by asking colleagues. Change moves slowly because nothing is standard.

In the modern picture, you use one core way of working for standard flows. You define handover points and owners. Procedures match reality and are easy to explain to new joiners and auditors. Sites and brokers follow the same main flow, with controlled local variations. Change gets easier because you adjust one model, not ten versions.

Jens Vandaele, Danone’s EU Customs and Trade Compliance Manager, shared a practical example of standardisation through a monthly global “customs community” that started at the beginning of 2024. They gather everyone involved in customs operations, share processes, discuss best practices, and work across the three pillars of origin, classification, and valuation. Jens described that this has increased attention on customs and on the procedures in place.

The process poll results were telling. Attendees were asked how standardised and efficient their customs process was:

Poll Question Two: Process

How standardised and efficient are your customs processes?

- 14% said processes differ by country or broker, with little documentation.

- 59% said Standard Operating Procedures exist but are not consistently followed.

- 16% said they have standardised procedures across main sites with KPIs tracked.

- 5% said automated workflows ensure consistency and quality control.

- 7% said processes improve using data and analytics.

Automation helps because the system guides the work step by step, so everyone follows the same process. It reduces variation across different locations and brokers, and makes training and audit explanations much easier.

Data: how to reduce customs delays caused by avoidable errors

The webinar called data the heartbeat of modern customs. It also cited a 2025 study by Customs Support Group and BCG: customs clearance in Europe takes around two to three days on average, and around 20% to 40% of delays come from avoidable classification or documentation errors.

In the old world, customs data is scattered. ERP shows one thing. A broker files another. Someone maintains a third version in Excel. Ownership stays unclear. Errors get found after filing. Time goes into rework, amendments, credit notes, and explaining differences. Reports get built for audits, not for improvement.

In the modern picture, one team owns customs data, and changes follow a clear flow. Key fields align across ERP, brokers, and customs systems. Checks catch issues before submission, not weeks later. Corrections drop. Data becomes something you use to steer decisions, not only to defend past choices.

Ludo Demeyere, Customs4trade’s Director of Strategic Customer Engagement, described what “future proof” starts to look like. "You bring information into one place in the same format, a control tower or data hub. That alone unlocks insight. From there, you can feed analysis tools." He shared an apparel example where procurement could see the impact of switching supply chains from country A to country B, including anti-dumping exposure, duty rates, and landed cost impacts.

The data poll results showed where teams stand today. Attendees were asked how well their customs data is managed and integrated:

Poll Question Three: Data

How well managed and integrated is your customs data?

- 34% said data is fragmented across spreadsheets, brokers, and systems.

- 34% said they have a basic data structure maintained locally.

- 12% said they have centralised, cleansed data feeding dashboards.

- 7% said data is integrated and validated, exchanged automatically.

- 12% said data supports forecasting, risk analysis, and decision support.

Automation helps most when it validates data before submission and reduces retyping across systems. It also helps you build one version of the truth you can actually use.

Technology: what a customs control tower looks like for EU and UK operations

Technology is where many teams want to start, but the webinar message was clear. It becomes a multiplier once you improve people, process, and data.

In the old world, key steps happen outside the systems meant to support them. People type the same data into ERP, broker portals, and customs tools. Even stable flows get manual treatment. Status depends on chasing updates.

In the modern picture, systems hold the core work instead of emails. Data flows from ERP into customs and broker tools without retyping. Standard flows run as far as rules allow. People work from exception lists and focus on what needs review. Status and risk are visible on simple screens.

A control tower example came up in the discussion. A company had moved from working with 60 brokers to a single broker for EMEA, with SAP feeding one European platform that then feeds local systems. They gained full transparency across imports and exports and could run analytics on one dataset.

Ludo explained why many organisations need a layer on top of their ERP system. The ERP holds transactional data. Customs needs additional documents, certificates, applications, and authorisations. A customs layer can enrich data, give control, and provide an overview of everything happening across the process. He linked this to the direction of customs reform, where companies will need data available in one place.

The technology poll results showed the current picture of what best describes attendees' technology landscape:

Poll Question Four: Technology

What best describes your technology landscape?

- 24% rely on Excel, emails, and brokers.

- 35% use limited digital tools that are not connected to ERP or WMS.

- 24% have partial connectivity via data exchange.

- 14% use an automated customs platform integrated with ERP and authorities.

- 3% use advanced automation with AI-driven analytics and monitoring.

Both Ludo and Jens stressed a hybrid reality. You do not automate everything. You automate repeatable flows and manage exceptions manually.

Governance and compliance: how to build audit trails without extra admin

Governance and compliance is where rules meet daily operations. The webinar tied this directly to EU Customs Reform, CBAM, and EUDR. Scrutiny increases. Compliance relies more on complete, reliable data.

In the old world, you only see the full picture when someone asks for it. You rebuild the story from emails, files, and reports. Controls happen in bursts around audits. Issues surface late. Lessons stay local, and problems repeat.

In the modern picture, you track Key Performance Indicators (KPIs) regularly. Dashboards give views across sites and brokers. You build checks into the process through sampling and simple rules. Alerts highlight unusual patterns before they become findings. Issues feed back into training, data, and process.

Ludo described how automation supports governance in a practical way. Teams build legal content into validation checks before declarations get sent. People work more from a “black box” approach, where they manage by exceptions and add only what is needed. He gave a concrete example. If a shipment is an organic product into the UK, the system checks for the right certificates and authorisations. If something is missing, the system stops the declaration and forces the data to be compliant before submission. He also described helping clients write Standard Operating Procedures for specific errors, similar to how Danone trains warehouse operators on basic checks.

The governance poll results showed how attendees track performance and ensure compliance:

Poll Question Five: Governance/Compliance

How do you track performance and ensure compliance?

- 31% rely on reactive audits with limited control or visibility.

- 46% run periodic checks and manual reports.

- 14% track KPIs and dashboards regularly.

- 9% use real-time monitoring with alerts and audit trails.

- 0% run continuous improvement driven by analytics and insights.

Automation helps here because it puts checks and evidence inside the workflow, not on top of it.

The benefits of customs automation for customs teams

The webinar examples pointed to the same outcomes.

-

You reduce manual workload by removing retyping and email-based checks.

-

You prevent avoidable errors by validating before submission.

-

You resolve issues faster because you see what is happening in real time.

-

You reduce dependency on brokers for basic status and data.

-

You improve control because checks, decisions, and audit trails sit in the system.

Danone framed this as three focus areas for customs. Cost, compliance, and continuity. They linked customs work to productivity, licence to operate across origin, classification, and valuation, and readiness for upcoming change.

A real-world example of modernising customs from the webinar: Danone

Danone shared a practical automation journey that started long before today’s reforms. They began in-housing customs in 2009 for Belgian exports. They moved away from early web tooling because it was not user-friendly. Brexit pushed the need for multi-country coverage and better control.

They described a “single message, double filing” approach. One ingest message from SAP contains basic logistics data. They combine it with master data and decision tables in the customs system, then file two declarations. First to Belgian authorities for export, then, after release, a second declaration to UK HMRC. This approach creates two declarations from a single message and supports a smoother flow.

Jens shared the scale. In 2024, they reached more than 40,000 self-filed declarations across Belgium, France, the UK, and Ireland. He also stated that self-filing represents 20% to 30% of their total declaration volume, so they still see room to bring more in-house.

They also described what they want next. They want to use automation to free operational workload and shift focus from repetitive execution to governance and monitoring. They want fewer dependencies on brokers, lower cost, better data reliability, fewer manual interventions, and “first time right”.

The Q&A at the end of the webinar gave a strong example of “not everything is automatable”. Jens mentioned IPAFFS (Imports of Products, Animals, Food and Feed system) for importing fresh dairy products into the UK. No API exists, only a web platform. Their team is working with IT to build a robot that collects the needed data from their systems and submits it into IPAFFS, so they can still move toward a more automated process.

Jens also shared a high-impact change from the last 12 months. They integrated returned goods relief with the traceability needed to link imports into Ireland back to the original export, reducing unnecessary duty payments in a UK and Ireland setup that operates as one market unit.

The common challenges of modernising customs, and how to beat them

- The blockers from attendees tell you where most teams get stuck. Integration gaps, data inconsistency, and dependence on brokers create manual work and hide visibility.

- The webinar also made one practical point. Start with people, as they determine everything else. If you invest in skills and a clear view of where you want to be, you can improve data, processes, tools, and governance.

- From there, focus on what reduces manual work fastest. Standardise how you work. Bring data into one consistent place. Add validation checks before submission. Build exception lists and dashboards so you stop chasing updates.

How automation supports EU and UK customs operations

The webinar gave a clear view of what automation does when it works well.

-

It reduces repetitive execution and frees capacity for governance and monitoring.

-

It supports self-filing where that makes sense, giving more control over data and fewer broker dependencies.

-

It supports a “manage by exceptions” way of working, where people intervene only when needed.

-

It embeds checks before submission, using legal content and rules, so you stop non-compliant declarations early.

-

It supports consistent handling of errors through clear Standard Operating Procedures and guided steps.

Automation also supports strategic value. Danone described building an end-to-end process for preferential origin determination integrated into ERP and trade systems, to standardise how they calculate and document origin. They linked this to better use of free trade agreements and reduced unnecessary duties. They also described a global classification project to create clear roles, responsibilities, and workflows worldwide.

Making the financial case internally

The webinar showed how to build a solid case for modernisation without vague promises. Start with outcomes your stakeholders already care about, then show how automation changes the mechanics behind them.

Lower operating cost

Automation cuts the work that creates repeat handling, broker chasing, and rekeying. Fewer touchpoints per shipment means fewer hours spent on data entry, fewer corrections, and less reliance on individual inboxes.

Lower duty and cash tied up

When you improve traceability and data quality, you apply the right reliefs and preferences more consistently. You also avoid overpaying due to missing evidence, wrong setups, or inconsistent use of special procedures.

Fewer disruptions

Automation reduces avoidable errors that trigger holds, rework, and expediting. Standard checks and consistent data reduce the “something went wrong, find the email thread” cycle that slows down shipments.

Lower audit effort and exposure

When evidence sits inside the workflow, you spend less time pulling documents from brokers and shared drives. You also reduce the risk of gaps, because the audit trail forms as work happens, not after the fact.

Danone’s lens is useful because it frames customs in business terms, cost to serve, compliance exposure, and continuity of supply. That helps you move the conversation from “customs needs a new tool” to “the business needs a more controlled, measurable process.”

How to get started with modernising your customs operations

The webinar closed with a practical sequence.

-

Step one: Start by mapping where you stand across the five dimensions using the matrix. Identify where work is manual or person-dependent, and where you already have structure and system support.

-

Step two: Pick one or two priorities. In many organisations, process and data create the biggest drag. Focus on what reduces risk or effort fastest.

-

Step three: Fix the basics. Clarify ownership. Write simple Standard Operating Procedures for classification, origin, valuation, and key procedures you rely on. Agree one source of truth for customs data in your core systems.

-

Step four: Use customs automation software, such as CAS, to support that design. Reuse master data. Apply rules in the system. Remove retyping and email-based checks. Let the platform keep decision logs and run standard controls.

-

Step five: Connect the ecosystem. Link ERP, customs solutions, and brokers so everyone uses the same data and sees the same statuses.

-

Step six: Use reporting to guide improvement. Once the basics are in place, you can see where errors come from, which lanes and products cause issues, and where to adjust procedures.

-

Step seven: Don’t do it alone. Modernising and automating customs touches IT, supply chain, tax, and finance. Work with the right partners, brokers, and solution providers, and use their experience, benchmarks, and tools to avoid re-inventing the wheel and move faster with less risk.

Try the Modernising Customs Online Quiz

Want a quick, practical way to benchmark where you stand? Take our online quiz to score your operation across the five dimensions: People, Process, Data, Technology, and Governance and Compliance. It takes less than a minute.

Modernising Customs Operations Webinar

Modernising Customs Operations Webinar

Want to see the full webinar? Click the button below to watch on demand.

Final takeaway

EU and UK customs teams face rising scrutiny and rising traceability demands. EU Customs Reform pushes more checks into central systems. CBAM and EUDR increase pressure on reliable data and evidence. Teams are stretched, and manual work does not scale.

Modernising customs operations means you reorganise work across people, process, data, technology, and governance and compliance. Automation makes this achievable by removing repetitive execution, validating data before submission, improving visibility through exception management, and embedding checks and audit trails into daily work.

Ready to explore further?

If you’re among the many businesses considering modernising and automating your customs processes, we can help you quantify the opportunity during a free customs strategy session. Our team can discuss the potential savings and compliance improvements.

We’ll also demonstrate how CAS automates every stage, from declarations and stock movements to period-end discharge reporting, so your team can focus on what really matters, running an efficient and compliant customs operation.

Get in touch today.

Q&A from the modernising customs operations webinar

What is the EU Customs Data Hub, and why does it matter for EU and UK customs teams?

The webinar message was clear. Customs moves toward central checks and data-led compliance. That direction increases scrutiny on data quality, consistency, and traceability. For EU and UK teams, this means you need cleaner data and better control across systems and partners. It also means you need visibility that does not depend on chasing updates.

How do you reduce customs rework caused by data errors?

The webinar cited that 20% to 40% of delays can come from avoidable classification or documentation errors. Reduce rework by validating key fields before submission and by reducing retyping across systems. Bring data into one consistent format, then use checks that stop non-compliant declarations before they get filed. This cuts corrections and late firefighting.

What does “manage by exceptions” mean in customs?

It means systems handle routine typing and checks, and people focus on what needs judgement. The webinar described this as working from exception lists and dashboards instead of inboxes. It also described a “black box” approach where validation checks run before submission. If data or certificates are missing, the system stops the declaration and forces correction early.

How does automation support governance and audit readiness?

Automation embeds checks into daily work. The webinar described validation checks using legal content before declarations get sent. It also described dashboards, alerts, and audit trails that capture what happened as part of the process. This shifts control from periodic manual reports to stronger visibility and evidence that does not require rebuilding the story from emails.